#Cut 40 plasma cutter circuit diagram drivers#

On the data sheet for the drivers it does say static sensitive! I think before I do any more I need to obtain so more screened 4 core cable of a few amps, fit plug and sockets and some extra filtering to the leads, such as 1 nF HV caps at the motors down to screen and some end to end Zener Diodes with caps in the control unit to add more protection for the HF start voltages. This was the result, but still an issue with the Z axis.īut better then blowing all three repeatedly. So to keep[ the job going see if I lost any steps etc I manually lifted and dropped the Z axis. It is also the one with the longest unprotected cable on the ends. the Z has been my worst axis for damage, I am guessing because it is holding the torch so closest to the high voltages all the time. Partway through the job the Z axis stopped, with noises so I had blown the Z driver, but X and Y kept running to the end. Checked the parallel cable and found the connection plug to plug was 10 ohms not zero, so replaced that with my trusted Belkin cable and tried again. First was all axis just stopped, no noises or anything, screen still saying things were moving, so stopped and reboot without plasma and all worked again so the parallel port had locked.

#Cut 40 plasma cutter circuit diagram update#

OK update and close on this, had two issues on removing the earth from the frame and trying a cut. next step loose the grounding of the frame. several updates to this as I think of things. Just thinking that rather then give the High voltage return several routes through all the grounding cables up to the control unit I will just have it going back to the Plasma. There is no continuety between the windings and motors, but this is not to say they do not break down with the high voltage spikes from the HF.

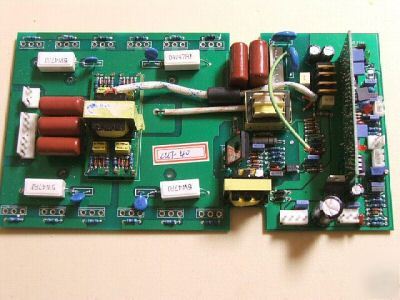

basically taking the earth ground off the frame and motors. The frame I will leave just connected to the return clamp to the plasma cutter and the earth wire on the nozzle still to the clamp. I am down to 3 chips left and one controller still to fix, (I have 3), considering I did not used to have such a failure rate I am considering just having grounds between the Plasma cutter unit and the control unit. Now the negative of the PSU is connected to a common ground in the control board PCB. left hand side is all the Opto-isolators for the input side to the TB6560 chips. Last picture if of the board, sorry fuzzy but all taken with camera phone. The green ground wire goes off to the Clamp which is clamped again to the Plasma frame and back to the negative terminal on the plasma cutter:.

Next is the copper ground connected to the nozzle, the idea of this is to stop the sputtering, if possible and provide a sort of pilot earth. Inside shot of the box, again note the grounding stubs bottom left of the door area, three green wires go up to the screens on the output cables, also there is connection from the door earth stud to the main box earth sud and the mains is also filtered:. OK some pictures, first one is the grounding connection to the back of the plasma unit, ,įrom here it goes to to the underside of the main frame and the disposable frame the metal being cut sits on:-įrom here a grounding strap goes up to the control box, bottom left of the picture:. So not a case of one part open but both outputs of the chip just very low output. Have toi use AC on the meter during stepping as it switched pos to neg, neg to pos etc. On a duff drive either X or Z axis I only get around 6 Volts AC. On the Y axis that still works when I move a stepper motor I get 25 Volts AC across the AP and AM connections and the same across the BP and BM windings. A few pictures taken these are below and I also put back in my duff control board before I repair it. The power supply is a Lambda power supply as mentioned.

Run the plasma up with out covers and the HF unit is not running all the time, just on start-up and when the nozzle goes over a hole when you can hear the sort of juddering when it takes out the control gear. OK just managed to get 20 minutes in the garage.

0 kommentar(er)

0 kommentar(er)